Custom hose fabrication can be expensive, especially if you choose inferior materials. A poor hose can cost you an average of $1000 per hour to produce, as well as a mechanic’s wage, product lost, and clean-up costs. So before you make your decision, take the following factors into consideration:

Field-Attachable Couplings

Custom Hose Fabrication is often required in applications involving high-end-pull pressures, flexing, and more rigorous processes. While this process takes more time and money upfront, it can ensure long-lasting performance and reliable connections. Custom hose fabrication can include a custom coupling built into the hose wall. Another option is a one-piece coupling with a ferrule that is permanently attached.

Custom hose fabrication requires the use of specialty materials and methods. The materials are evaluated in detail, and the hose is fabricated according to your specifications. The manufacturer must also be familiar with the chemicals and pressures used in your application. The hose’s inside diameter vital because it determines how much pressure can be applied. If the pressure is too high, it may lead to premature hose failure and clogging. In addition, a hose with a large inside diameter hose can have trouble routing and cost more than is needed.

PTFE

In calculating PTFE custom hose fabrication costs, you must consider your hose’s size and radius. You can apply the basic circle formula (circumference of circle = 2PR x radius) to the hose you plan to order. This formula assumes that your hose will have flange end fittings. In calculating your hose fabrication costs, you should also factor in the length of non-flexible end fittings.

The Corroline+ hose is the most flexible hose for chemical plant applications. It can operate in temperatures from -40degC to 150degF. The hose is also resistant to kinks and requires less force to bend than other smooth-bore PTFE-lined hose products.

Stainless Steel

Stainless steel custom hose fabrication costs are determined by the length of the hose you require and the size of the tube and fittings that will connect it. The length of the hose is usually much longer than the tubing that is used for assembling it. In some cases, the hose can be up to 500 feet long. Although metal tubing is typically available in 20-foot lengths, you can order more considerable lengths with an increase in cost and lead time. Additionally, the tube is more difficult to ship and store than a hose.

The fabrication cost is generally lower for hose assemblies than for tube assemblies. The reason is that hose assemblies are easier to manufacture and are available from many sources. Tube bending, however, is more complex and requires special tools and trade skills.

Textile-Braid

The layers that make up textile-braid hoses are numerous. The first layer is the elastomeric tube. The spiral sleeve with braiding is the second layer. Each braiding member comprises a bundle of wires with high tensile strength and low elongation. The wire may be brass plated for increased tensile strength and adherence to the elastomeric material. The wire’s gauge must meet the hose’s load-bearing requirements.

Textile-braid hoses are similar to textile weaves in terms of their production process. They are created by alternating the direction of yarn carriers (called warp and weft) while weaving them together. However, unlike weaves, braids differ in their textile structure. The angle between the yarn systems in braids is less than 90 degrees.

SAE Specifications

If you’re interested in hose fabrication, you may have heard of SAE specifications. The minimum pressure ratings, dimensional specifications, and other details for hydraulic hoses are described in these standards. These specifications include all aspects of construction and design, including fluid compatibility. These criteria are used by manufacturers to guarantee uniform product quality across all brands.

Hydraulic hose assemblies transmit energy via compressed air and hydraulic fluids and contact hundreds of thousands of workers daily. The use of SAE specifications can ensure their safety and performance.

Price

In addition to the quality and speed of production, the price of custom hose fabrication varies. If you want a custom hose for a specific application, a manufacturer should carefully assess the parameters of your application and evaluate the materials used. Ideally, it would help if you chose a manufacturer that uses the best materials for the job.

You can contact a hydraulic hose manufacturer specializing in custom hose fabrication if you need to make a hose for an industrial application. However, custom hose assemblies do not have a money-back guarantee, so it is best to contact a company before placing an order.

Permanent Couplings

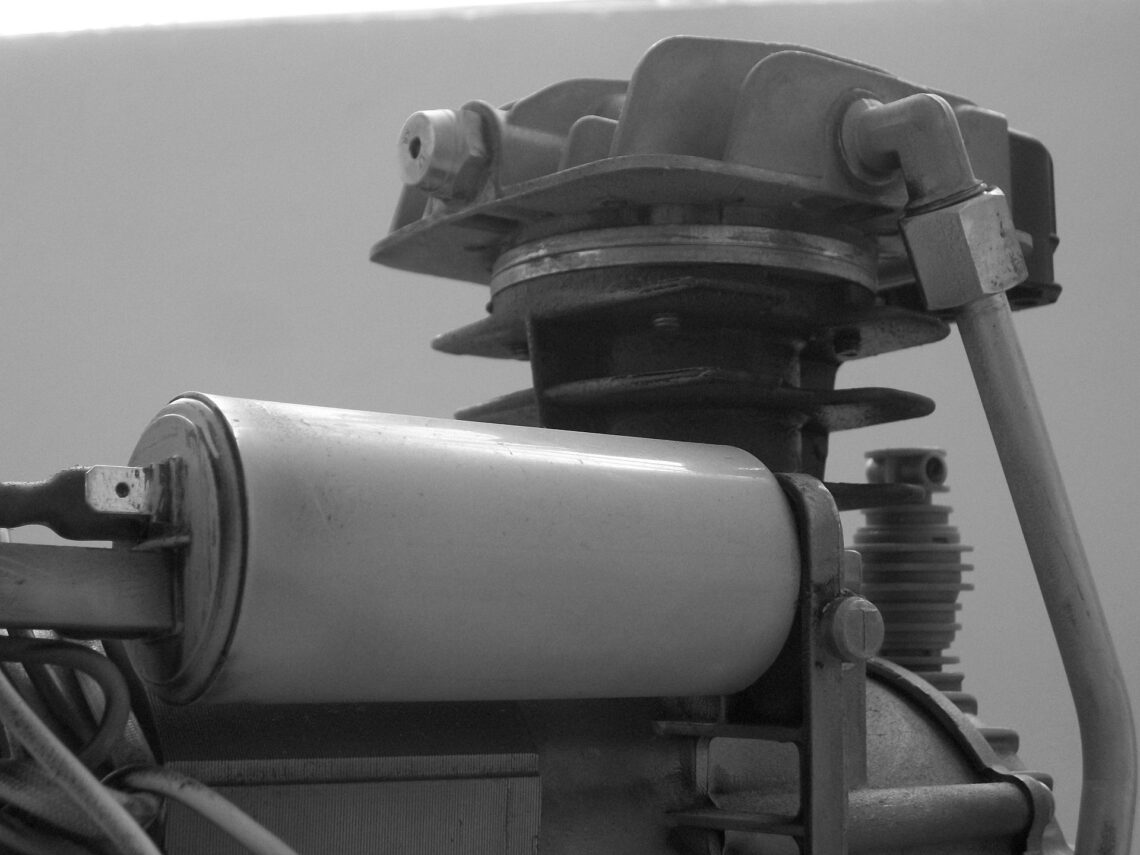

The modern hydraulic hose industry is undergoing a revolution, with increased performance requirements and globalization of equipment platforms. Advances in materials and assembly processes have made it possible to produce hoses that outperform dated standards. But proper assembly is essential to achieve maximum performance. For this reason, there are a variety of options available.

First, it is essential to consider the bending radius. This should be a minimum of one hose diameter and consistent with its natural curvature. It is important not to bend the hose immediately after it is attached to the coupling; this will result in a shorter lifespan. It is also essential to avoid using the hose as a step or grab handle.